Services

Energy Associates is a

professional corporation that provides engineering and consulting services for

projects at ports,

terminals, power plants, transportation, mines, and the minerals/process

industries. We assist: owners,

developers, A/E firms, industrial enterprises, financial and banking

institutions, utilities, governmental agencies, and EPC Contractors. Energy Associates is often part of an

engineering team, providing specialty expertise that allows the project to move

forward quickly in the right direction.

Assignments and responsibilities include:

- Expert Witness – Technical Assistance in

Investigation, Mediation, and

Litigation

- Feasibility Studies

- Technical Bid

Specifications

- Detail Design

- Compliance Reviews

of Contractor Design Submittals

- Failure Analysis and Troubleshooting

- Technical Requisitions and Material Purchasing Support

- Construction Compliance Monitoring

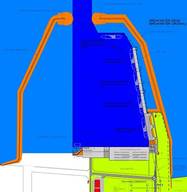

Energy Associates specializes in bulk material

handling, blending, processing, storing, and transloading. The equipment installed on systems

includes: belt conveyors, pipe conveyors, drag conveyors, screw conveyors,

airslide conveyors, en-mass conveyors, Flexowell conveyors, high-angle belt conveyors,

belt feeders, vibrating feeders, rotary plow feeders, screw feeders, vibrating

screens, rotary screens, traveling stackers, radial stackers, bucket-wheel

stacker reclaimers, scraper reclaimers, shiploaders, grab bucket ship

unloaders, continuous screw ship unloaders, continuous ladder bucket unloaders,

pneumatic ship unloaders, self-unloading vessels, traveling trippers with silo

storage, crushers, breakers, pulverizers, ball mills, bowl mills, dust

collection, dust suppression, pile spray systems, conveyor washdown systems,

belt scales, sampling systems, transfer structures.

Projects

|

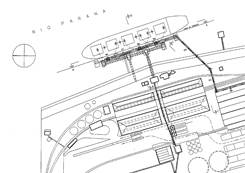

Ports,

Terminals, and Processing Plants |

|

|||||||

|

||||||||

|

|

|

|||||||

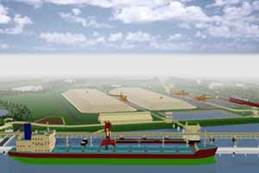

![]() While our primary projects have been in the US, Energy

Associates has assisted on assignments in Colombia, Ghana, India, Indonesia,

Italy, Liberia, Malaysia, Philippines, Poland, Thailand, Venezuela, United Arab

Emirates, and the United Kingdom. In

previous employment, our team has worked on projects throughout Asia and South

America.

While our primary projects have been in the US, Energy

Associates has assisted on assignments in Colombia, Ghana, India, Indonesia,

Italy, Liberia, Malaysia, Philippines, Poland, Thailand, Venezuela, United Arab

Emirates, and the United Kingdom. In

previous employment, our team has worked on projects throughout Asia and South

America.

|

Fuel

Handling Systems at Power Plants |

|||

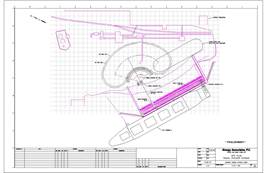

Detail Design

Once the

system’s functions, attributes, layout, and transitions are established,

the detail design of each belt conveyor is the focus for executing a

project. Mechanical calculations

are normally the first priority to determine conveyor horsepower, belt

tensions, pulley sizes and other parameters that are important to the selection

and application of manufactured components including:

1. Drives:

gearbox, chain, v-belt, cog-belt, hydraulic, and fluid drives.

2. Drive

components: holdback backstops; brakes; couplings, and fluid couplings.

3. Conveyor

components: pulleys; troughing, transition, impact,

training, return, and V-return idlers; belt scrapers; and belt plows.

4. Safety

devices: emergency stop, speed, pull cord, belt alignment or misalignment, plug

chute, and other field devices.

Designs that

understand and critically analyze conveyor parameters, equipment selections,

and applications are synonymous with success. The goal is to minimize the potential

for accidents, problems, failures, and disputes.