Fuel Blending

System Program

for the

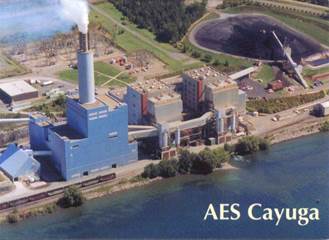

300 MWe AES Cayuga Plant

Client

AES Cayuga

228 Cayuga Drive

Lansing, New York 14882-8896

Completion Date

May, 2008

Project Description

Energy Associates was engaged

by AES Cayuga to investigate the addition of a fuel blending system.

Energy Associates completed the original feasibility study and upon project

approval, completed the detail design and reviewed/approved contractor

submittals for this project.

The

AES Cayuga Plant (previously the Milliken Station) consists of consists of

Units No. 1 and 2 commissioned in 1955 and 1958. Each pulverized coal

boiler is rated roughly 150 MWe. In 1994, an

SCR was added to unit No. 1 and a FGD system was added for the plant.

Some changes where made to the coal stockpile area

and bunker outlets/feeders. Some of the original coal handling equipment,

such as belt scales and a sample system on the reclaim system, have been

removed.

The

AES Cayuga Plant (previously the Milliken Station) consists of consists of

Units No. 1 and 2 commissioned in 1955 and 1958. Each pulverized coal

boiler is rated roughly 150 MWe. In 1994, an

SCR was added to unit No. 1 and a FGD system was added for the plant.

Some changes where made to the coal stockpile area

and bunker outlets/feeders. Some of the original coal handling equipment,

such as belt scales and a sample system on the reclaim system, have been

removed.

For AES Cayuga, fuel is

the plant�s major operating cost. It has been targeted as a potential

source for reducing plant cost and improving plant dispatch. Because the

plant is already fitted with an FGD scrubber, it can utilize high sulfur

opportunity fuels, blending it with its base, Pennsylvania coal for

instance. Petroleum coke is an example being considered by the

plant. This is a high sulfur, high heating value fuel. Because

petroleum coke is low in volatile matter, it cannot be directly combusted in

most pulverized coal units as the primary fuel. Blending petroleum coke

with a relatively high volatile coal, which is the plant�s primary fuel, is a

successful strategy being used by some pulverized coal power plants.

AES Cayuga�s coal handling

system was designed to efficiently unload, crush, and reclaim a single

coal. The existing, fixed, luffing stacker is an obstacle to segregating

piles. There is only one discharge point. Complicating plant

operations, the discharge point is located directly over the reclaim hoppers,

coal that is to be segregated must be immediately bulldozed away from the

discharge of the stacker. Otherwise, the reclaim hopper directly below

will feed this coal to the bunkers. If this is not promptly and carefully

done, a slug of low-grade fuel can be feed to the boiler upsetting plant

conditions. Conversely, reclaiming slugs of higher, more costly grade

fuels frustrate the plant�s ability to minimize fuel cost. The plant has

received different coals by rail and truck, experimenting with a rudimentary

blending arrangement using mobile equipment. This effort highlighted the

need to consider modifications that will improve blending control and

consistency.

Handling a second fuel and

blending the two required modifications/additions to the coal handling

system. Energy Associates examined a variety of concepts in the

feasibility study. A unique feeder/conveyor concept was developed, which

allows the plant to blend fuel with the addition of a single, major component �

the feeder/conveyor. The feeder/conveyor also increases fuel system

redundancy and reliability, allowing the plant to continuing reclaiming coal if

the primary reclaim hopper is out-of-service.�

Illustrated blow is the low speed hydraulic drive motor that enables the

feeder/conveyor to operate with infinite belt speed variation from 15 to 300

fpm, a capacity range of 30 to 600 tph.