�for

Nucla�s In-Plant Coal Handling System Modification

Client

Tri-State

G & T Association

Nucla Plant

P.O. Box 698

Nucla, Colorado

Completion Date

June, 2000

Project

Description

Tri-State's Nucla Station was experiencing boiler

tube wear due to an excessive amount of rock being mined with a local source of

coal.� To alleviate this problem,

Tri-State approved the addition of a rotary breaker to both crush the coal in

its secondary stage and separate rock from the fuel.� Tri-State engaged Energy Associates to

support their efforts on this project.

Energy Associates was

responsible for the detail design engineering for the mechanical, structural

steel, electrical, and I&C portions of the project.� In addition, Energy Associates provided

foundation loads to assist Tri-State in engineering the foundations.

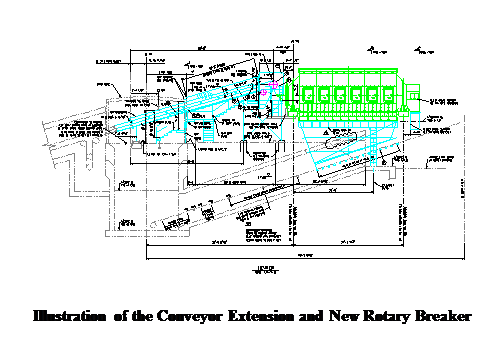

The breaker replaced the

existing secondary crusher.� Conveyor No.

1A, which feeds this crusher was extended though the north wall of the existing

crusher house.� The breaker was located

above a tunnel that received the secondary crushed coal and elevates it above

grade. �The completed installation and a

general arrangement drawing illustrate this modification.