Feasibility

Study

for a

Self-Unloader Ship Receiving System

|

Client |

and |

|

Completion Date

October, 1997

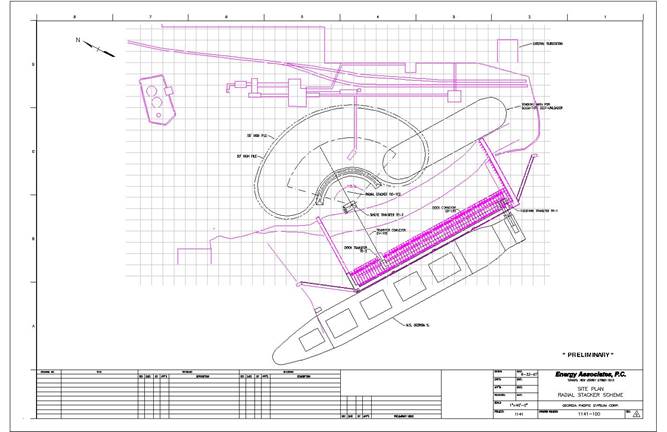

Project Description

Georgia Pacific considered modifications to ship unloading facilities for their

Camden, New Jersey Plant. Gypsum is

received via self-unloading vessels with boom conveyor discharge. These vessels discharge gypsum directly

to a stockpile, adjacent to the shoreline.

Utilization of the M/V Georgia S was being considered. Employment of the M/V Georgia S in this

movement can provide four potential benefits. It would reduce transportation

costs. The gypsum pile can be

immediately stacked away from the shoreline. This reduces geotechnical/stability

impacts on the sloped shoreline and possibly allows a higher stockpile to

increase storage capability. The

modifications would reduce the potential of erosion, product loss, discharge,

or contamination of gypsum into the Delaware River. The amount of double handling that is

presently necessary (to the clear the gypsum pile area stacked by the

self-unloader boom for the next vessel) would be reduced.

Energy Associates investigated

alternate schemes for the conveying and stacking system. Two schemes were developed. They were illustrated in plan and

elevation study drawings. Project

appropriation budget level estimates were prepared and the findings were

summarized in a study report. One

scheme is illustrated below.