Relocating

the South No. 6 Tower

at the

Labadie Plant

Client

Union Electric Company

Union Electric Company

(now Ameren)

End of Bottom Road

Labadie, Missouri 63055

Completion Date

December, 1996

Project Description

The

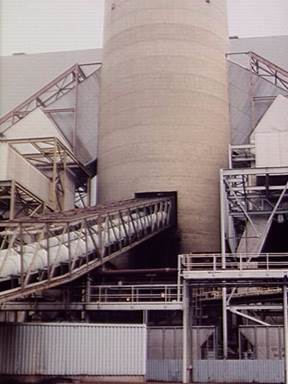

4x600 MW Labadie Plant has three stacks. Units No. 1 & 2 each have an

individual stack located directly behind each unit. Units No. 3 & 4 have a common stack,

located between the units. The two flues are placed within an outer shell. As seen in the photo to the right, the

coal reclaim conveyors are routed through the lower portion of the shell. The conveyor take-up for tensioning

these belts was attached to the outer casing of the Unit No. 3-4 stack.

In response to the lower sulfur

requirements of Clean Air Act Amendments, plant fuel was switched to PRB coal

in 1991. PRB coal is dustier and

more reactive than Illinois coal.

As  a result, a dust problem became apparent

at the Unit 3-4 stack take-up location.

Belt flexing at the take-up pulleys released fine dust particles, which

became airborne. They were then

swept into the interior of the common stack shell by the natural chimney draft.

The large coal particles fell into a pile, which accumulated at the base of the

shell. The coal fines drifted

upward to accumulate at inaccessible locations within the common stack

shell. There they caused fires and

created an explosive hazard.

a result, a dust problem became apparent

at the Unit 3-4 stack take-up location.

Belt flexing at the take-up pulleys released fine dust particles, which

became airborne. They were then

swept into the interior of the common stack shell by the natural chimney draft.

The large coal particles fell into a pile, which accumulated at the base of the

shell. The coal fines drifted

upward to accumulate at inaccessible locations within the common stack

shell. There they caused fires and

created an explosive hazard.

The belts were experiencing

tracking problems. Coal was

accumulating on the take-up bend pulleys.

During the winter, this coal froze to the pulleys increasing belt misalignment. The conveyors are relatively long,

approximately 900 feet. They extend

from grade to the surge bin above the plant silos. The misalignment problem

"chewed-up" the edges of the belts, damaging approximately two-thirds

(2/3) of a mile length of belt for the two conveyors.

To

correct these problems, Union Electric engaged Energy Associates to examine the

possibility of relocating the take-up.

Energy Associates investigated alternatives and recommended a

horizontal, gravity arrangement.

The take-up was located at grade where it is accessible. Features to improve maintenance and

clean-up were incorporated into the design. Energy Associates prepared the detail

design drawings, material purchase requisitions, and construction

specifications for this retrofit.

The horizontal take-up is seen in the above photograph taken during the

construction period. The counter-weight

tower is seen to the right.

To

correct these problems, Union Electric engaged Energy Associates to examine the

possibility of relocating the take-up.

Energy Associates investigated alternatives and recommended a

horizontal, gravity arrangement.

The take-up was located at grade where it is accessible. Features to improve maintenance and

clean-up were incorporated into the design. Energy Associates prepared the detail

design drawings, material purchase requisitions, and construction

specifications for this retrofit.

The horizontal take-up is seen in the above photograph taken during the

construction period. The counter-weight

tower is seen to the right.